Add to Cart

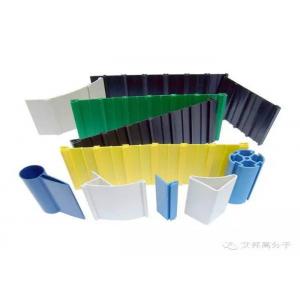

PVC Profile Machine , PVC Wall Panel , Plastic Extruder , PVC Ceiling , PVC Ceiling Machine

Components And Features:

PVC profile extrusion lines are applied for manufacturing PVC profiles for window and door, cable trunk, multi-holes pipe needed in field of architecture, telecom communication, etc..

The complete extrusion consists of following items:

SPECIFICATIONS:

| MODEL | Profile width (mm) | Extruder | Extruder power (kw) | Capacity (kg/hr) |

| LB-108 | 108 | SJZ51/105 | 18.5AC | 100 |

| LB-180 | 180 | SJZ55/110 | 22AC | 150 |

| LB-300 | 300 | SJZ65/132 | 37AC | 250 |

| LB-500 | 500 | SJZ80/156 | 55AC | 350 |

Features Specifications:

1. Model SJZ series conical twin screw extruder is a kind of special equipment for extruding PVC compound. With different kinds of molds and auxiliary machines, it can produce all sorts of PVC plastic pipe, profile, plate material, sheet material, bar material and granulation.

2. The conical twin screws have applied oil cooling system. Barrel is cooled by special wind cooling system.

3. The conical twin screw extruder system has applied special computer control. According to customers requirements, most reasonable structure of conical twin screw can be made so as to achieve best plasticity performance and material quality.

4. The conical twin screw is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced advanced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut.

5. The distribution box is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged. It can bear larger extruding pressure.

6. The electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1degree.

Our service

Pre-sales service:

* Introducing in detail features and application of the products to customer

* Selecting economical and practical machine & equipment for customer

* Providing operation data of the related machine & equipment

* Providing means of trial performance for customer

Sales service:

* Recommending engineering conditions required for installation of the machine & equipment

* Communicating in time the manufacturing progress of the machine with the user

* Providing assistance in technical conditions, screw combination and barrel disposition needed for product

After-sales service:

* Providing on-the-spot technical assistance in installation, commission and training

* Filling in detail customer’s information

* Providing long-term maintenance service and spare parts

* Giving technical support to customer for developing new product

* Providing free maintenance for a year